Sports at extreme altitudes

2. May 2022

The way the human body reacts to training and competition at high altitudes above sea level has been studied for many years.

The main factor is the gradual decrease in barometric pressure and thus the partial pressure of oxygen in the inspired air, resulting in an increase in the athlete’s respiration rate.

Other factors, such as a decrease in temperature (approx. 1°C every 175 metres), a decrease in water vapour and the force of gravity as well as an increase in solar radiation, also come into play. Athletes thus have to give their body time to gradually adapt to these conditions when participating in high-altitude competitions and must take a series of measures such as prior medical check-ups, eating regularly and in moderation, increasing hydration and the frequency of training breaks, as well as protecting themselves against ultraviolet rays, especially by wearing sunglasses with highly protective lenses.

Many benefits are observed in athletes who train at high altitude: increased endurance, greater tolerance to fatigue, improved intracellular buffering capacity of the muscles, the capacity to maintain the body’s level of strength and increased recovery capacity.

Although you might think that the athletics tracks at the highest altitudes are found in Switzerland (averaging 600 metres above sea level), in the Rocky Mountains in Colorado (USA) at 1,600 metres or even the famous La Paz Stadium in Bolivia at just over 3,500 metres above sea level, the truth is that most of the world’s high altitude tracks are found in Peru, which boasts numerous athletics tracks located anywhere from 1,500 metres to over 4,000 metres above sea level.

At these altitudes, not only athletes but also manufacturers of athletic track materials, and even more so technicians in charge of installing these surfaces, have to overcome great challenges

As CONICA is the company with most extensive experience with certified systems for athletics tracks in the widest variety of climatic conditions, we have been chosen for numerous projects that have to handle and guarantee the installation of tracks in the most difficult conditions imaginable.

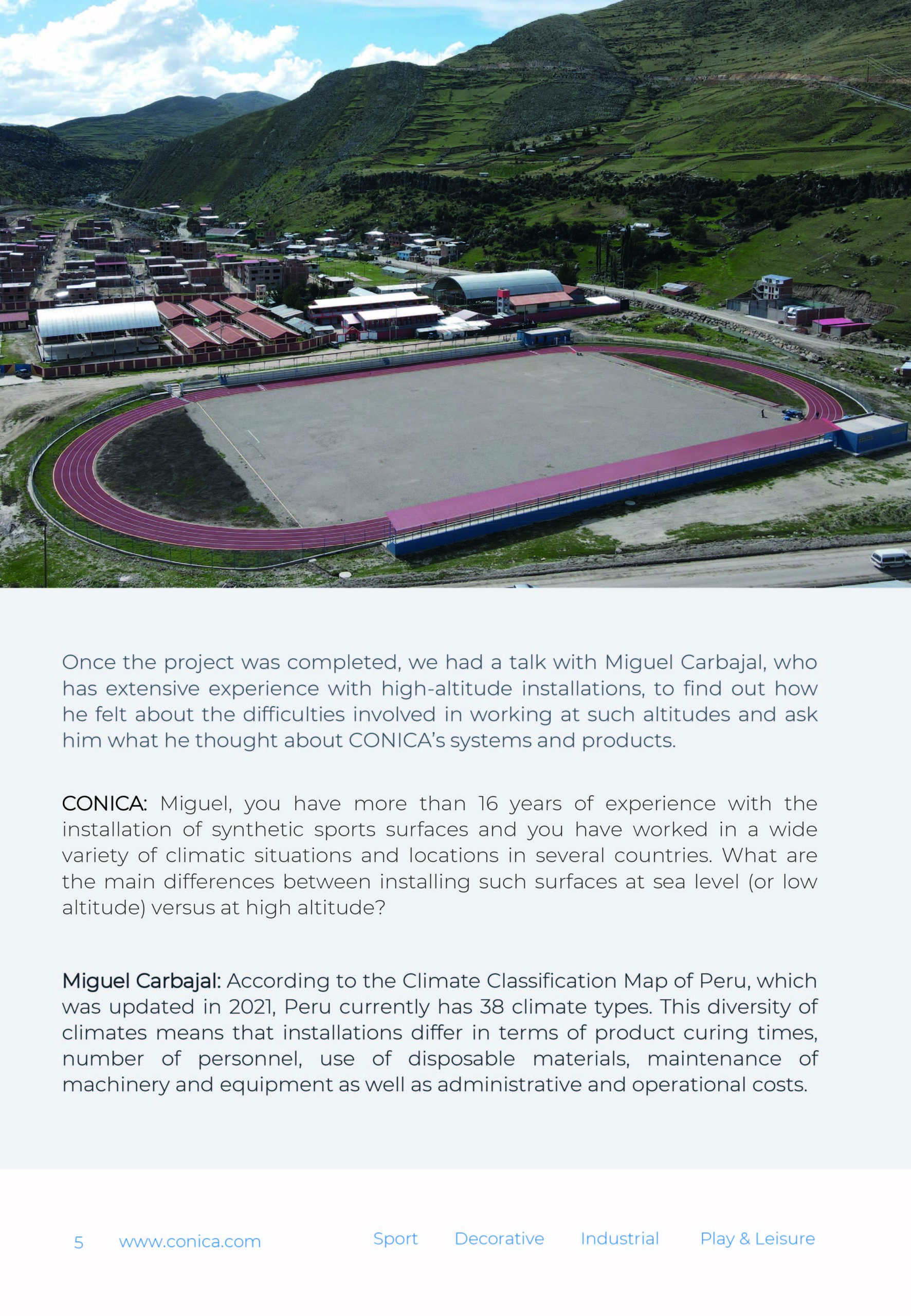

Our customer GABSport recently delivered the athletics track in Challhuahuacho, in the Department of Apurimac (Peru). It was installed by the team led by Miguel Carbajal (Sport System Peru), with whom we had a conversation in order to assess their degree of satisfaction with CONICA’s CONIPUR SW system. This is CONICA’s most popular pour-in-place system and is of course certified by World Athletics.

A new track a cut above the rest: “CONICA scales new heights”

Technical details of the project

- similar to RAL 3016

- System height: 14 mm

- Location: Challhuahuacho, Apurimac (Peru)

- Distributor: GABSport Peru

- Head installer: Miguel Carbajal (Sport System: CONIPUR SW in red, System Peru)

- Altitude above sea level: 3,698 metres

- Period of installation: From 22/11/21 to 08/12/21

- Maximum daytime temperature during period of installation: 15°C to 23°C

- Minimum night-time temperature during period of installation: 2°C to 7°C

- Average temperature during the year: 10 degrees

- Average humidity during installation: 61% – 70%

Once the project was completed, we had a talk with Miguel Carbajal, who has extensive experience with high-altitude installations, to find out how he felt about the difficulties involved in working at such altitudes and ask him what he thought about CONICA’s systems and products.

CONICA: Miguel, you have more than 16 years of experience with the installation of synthetic sports surfaces and you have worked in a wide variety of climatic situations and locations in several countries. What are the main differences between installing such surfaces at sea level (or low altitude) versus at high altitude?

Miguel Carbajal: According to the Climate Classification Map of Peru, which was updated in 2021, Peru currently has 38 climate types. This diversity of climates means that installations differ in terms of product curing times, number of personnel, use of disposable materials, maintenance of machinery and equipment as well as administrative and operational costs.

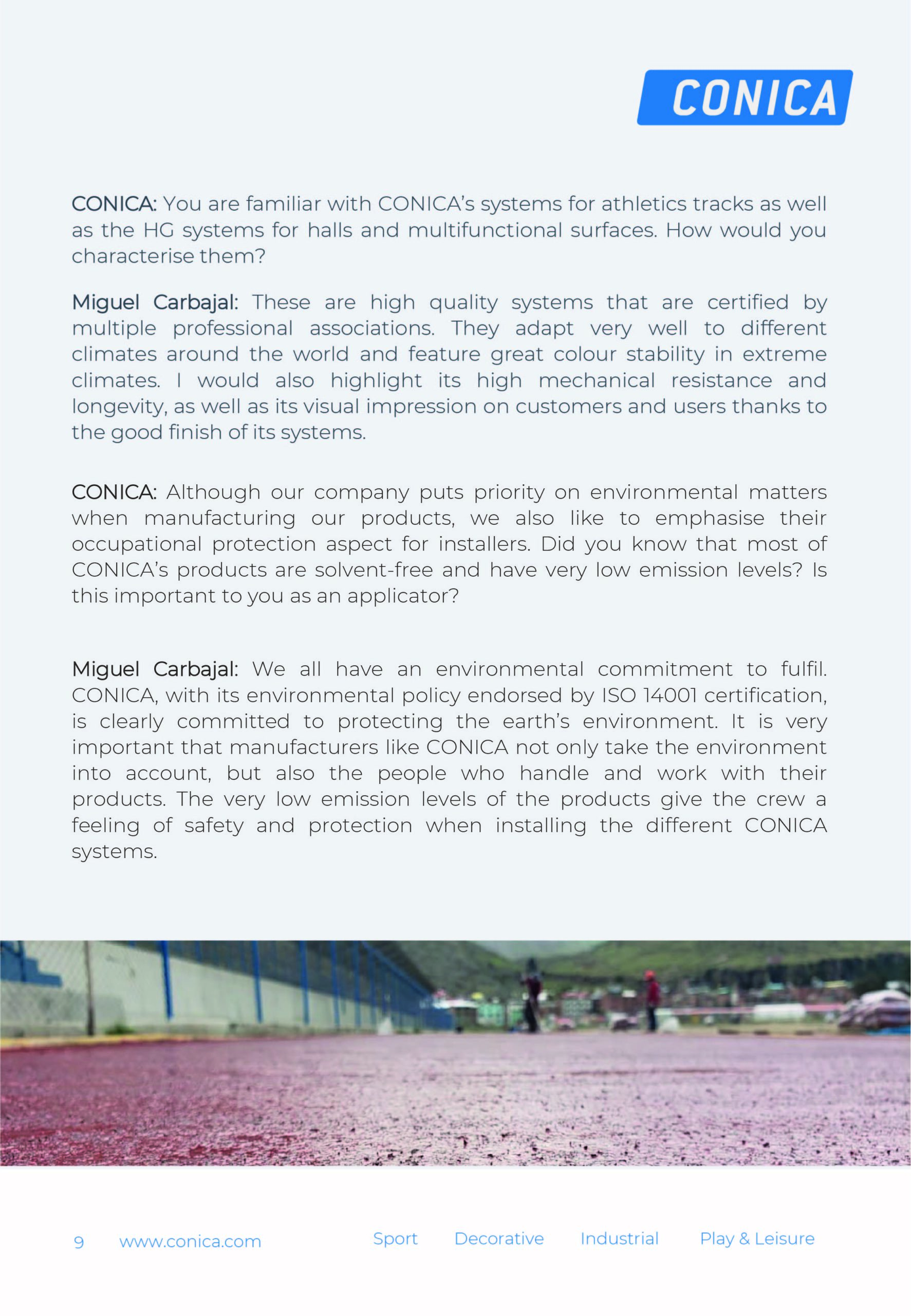

CONICA: As an installer, this type of project at higher altitudes surely constitutes an extra challenge. What additional aspects do you take into account?

Miguel Carbajal: We evaluate the altitude and climate, where we are going to carry out the installation, in advance for such projects. As prior evaluation gives us a better overview of the pros and cons that could be involved in the execution of the project, we can plan the procedure to be followed and thus prevent or minimise any damage to the products we install or apply. Our own procedure, which is based on experience, helps us follow a very precise implementation plan. We take into account, for example, the acclimatisation of personnel and recruitment of additional regional personnel to compensate for the daily progress we would make with a surface installed in a sea level climate. We also rely on local experts to assess the varying conditions, which helps us identify possible sudden changes in weather. We complement this with weather forecasting by means of geolocation applications.

CONICA: I imagine that chemical products also react differently depending on altitude and temperature. How do you rate CONICA’s products in this respect? Do they make your work easier?

Miguel Carbajal: The chemical reaction of the products indeed differs depending on the different types of climates in which these projects are implemented. As this is a multi-stage construction process involving different products and application windows, altitude plays a decisive role in product behaviour and natural curing. As a specialist, I have found that CONICA products do not deteriorate in this type of high-altitude climate, making installation easier in terms of application and curing times.

CONICA: You have already carried out other high-altitude projects – several of them with CONICA products – but you also have experience with various manufacturers’ systems. What do you think of our products, especially for this type of high-altitude project?

Miguel Carbajal: Indeed, we have implemented several projects at altitudes ranging from 3,000 metres up to 4,300 metres above sea level. Product behaviour with other brands has sometimes been very tricky. In some cases, polyurethane products changed their composition to such an extent that products such as binders almost congealed.

When installing comparable surfaces with CONICA products at altitudes of more than 3,600 metres above sea level, we experienced no major difficulty applying the different systems such as CONIPUR SP or CONIPUR SW in this type of climate, as their polyurethanes adapt well to extreme climates and conditions.

CONICA: You recently tested our new CONIPUR 2400 filler with lower consumption and higher viscosity. What do you as an installer think of the new composition?

Miguel Carbajal: As an installer, applying a sealant such as CONIPUR 2400 means lower consumption as well as higher productivity and speed. The high viscosity of the CONIPUR 2400 filler reduces leaching into the elastic base, which in turn leads to lower consumption. These two factors – lower consumption and higher viscosity – ensure greater all round costeffectiveness.

CONICA: How have CONICA products performed from a curing and processing point of view under the harsh working conditions?

Miguel Carbajal: Although the products show slight differences or alterations that are typical for an extreme climate, they did not undergo any major changes in chemical structure. We therefore did not have to wait for days for natural curing and processing (as sometimes happened with other brands), during which we cannot continue with the following layers. With CONICA we were able to finish the installation on schedule. As a specialist, I can guarantee that CONICA products are very well adapted to these types of climate.

CONICA: You are familiar with CONICA’s systems for athletics tracks as well as the HG systems for halls and multifunctional surfaces. How would you characterise them?

Miguel Carbajal: These are high quality systems that are certified by multiple professional associations. They adapt very well to different climates around the world and feature great colour stability in extreme climates. I would also highlight its high mechanical resistance and

longevity, as well as its visual impression on customers and users thanks to the good finish of its systems.

CONICA: Although our company puts priority on environmental matters when manufacturing our products, we also like to emphasise their occupational protection aspect for installers. Did you know that most of CONICA’s products are solvent-free and have very low emission levels? Is this important to you as an applicator?

Miguel Carbajal: We all have an environmental commitment to fulfil. CONICA, with its environmental policy endorsed by ISO 14001 certification, is clearly committed to protecting the earth’s environment. It is very important that manufacturers like CONICA not only take the environment into account, but also the people who handle and work with their products. The very low emission levels of the products give the crew a feeling of safety and protection when installing the different CONICA systems.

CONICA: Is there any other aspect that you would like to highlight about CONICA, such as its products or customer support and availability?

Miguel Carbajal: CONICA can be summed up in one word: IDENTITY. For the quality of its products, the innovation of its systems, the maintenance of its corporate image, its commitment to the environment and the availability of products at short notice.

As an installer and from a customer’s point of view, personalised service and support is very important because it helps us grow and learn more about CONICA. That’s why the support and advice we receive from the commercial manager of Latin America in every project we carry out makes us feel backed up not only by a brand, but also by plenty of experience and expertise.

CONICA: Thank you very much, Miguel, and congratulations for the quality of your work. We look forward to continue working with you for many years to come.

Miguel Carbajal: I am grateful to CONICA for giving me this opportunity to share my experience and know-how, and I hope interested people will find it very useful.

View the case study on a special project. Download PDF