Dubai Heights Academy

11. May 2021

Situated in Dubai with a British school system and an international spirit, the Dubai Heights Academy is an ambitious private school open to locals and pupils from abroad. The architecture is characterised by high-quality, sustainable materials, such as floorings from CONICA.

Just like in any other city with millions of inhabitants, there are also many highly qualified people from abroad working in Dubai who operate worldwide and move around a lot. During their stay, they look for a school for their children that complies with international standards. Local families are also beginning to recognise the benefits of an international private school. Founded in 2017, the Dubai Heights Academy is open to everyone – and thus aligns with Dubai’s ‘city for everyone’ motto.

The curriculum is closely based on the British school system and is comprised of the early years foundation stage, primary school and secondary school. The school can thus take in 1,800 pupils from the ages of three through to sixteen. To offer them a real school family, the school has been given a touch of Hogwarts with four ‘houses’ that are named after typical desert inhabitants: Wolves, Falcons, Gazelles and Scorpions. As well as this, teachers specially trained for inclusion are on hand to ensure that every single child receives the support they need.

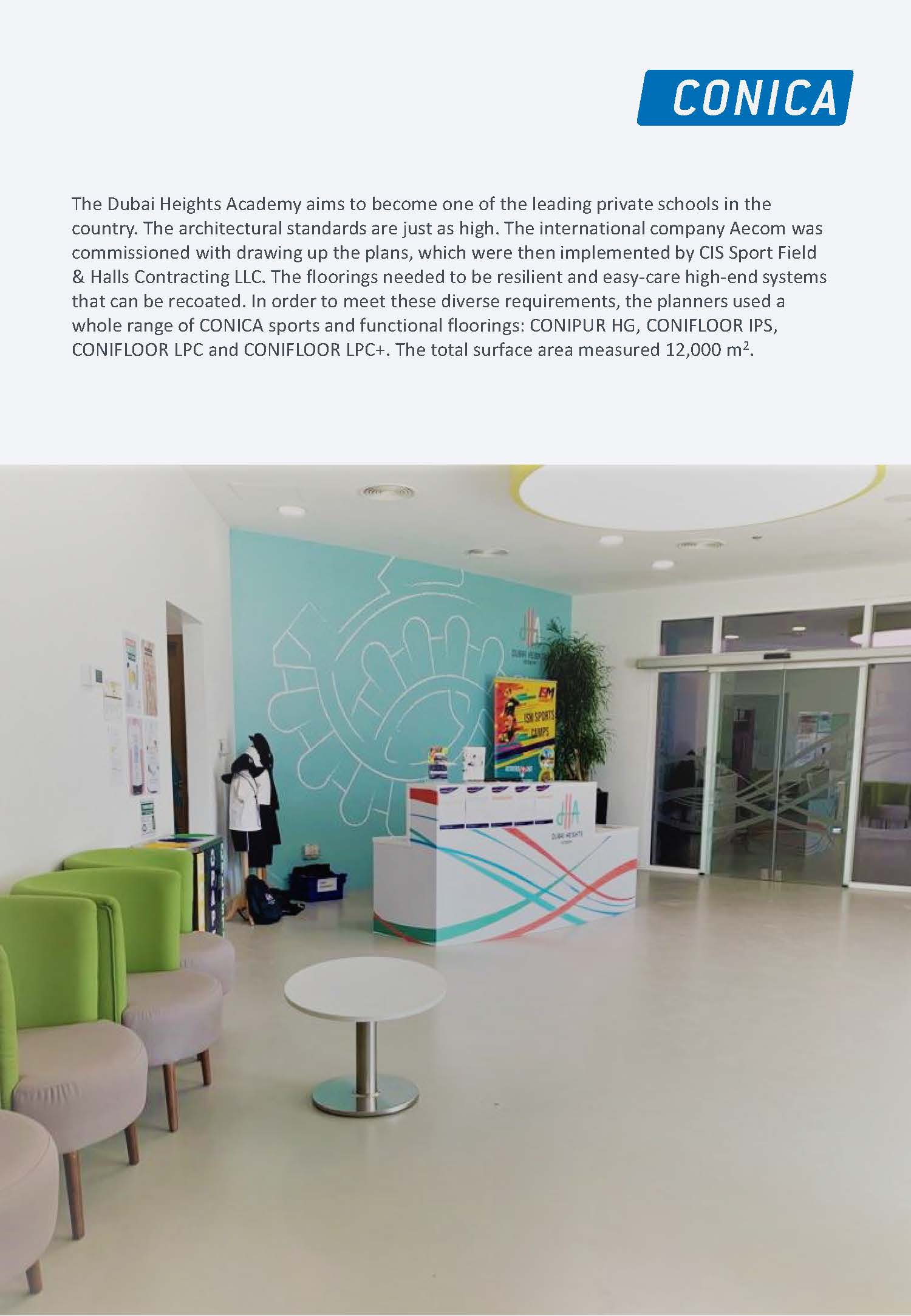

The Dubai Heights Academy aims to become one of the leading private schools in the country. The architectural standards are just as high. The international company Aecom was commissioned with drawing up the plans, which were then implemented by CIS Sport Field & Halls Contracting LLC. The floorings needed to be resilient and easy-care high-end systems that can be recoated. In order to meet these diverse requirements, the planners used a whole range of CONICA sports and functional floorings: CONIPUR HG, CONIFLOOR IPS, CONIFLOOR LPC and CONIFLOOR LPC+. The total surface area measured 12,000 m2.

Age-appropriate floorings

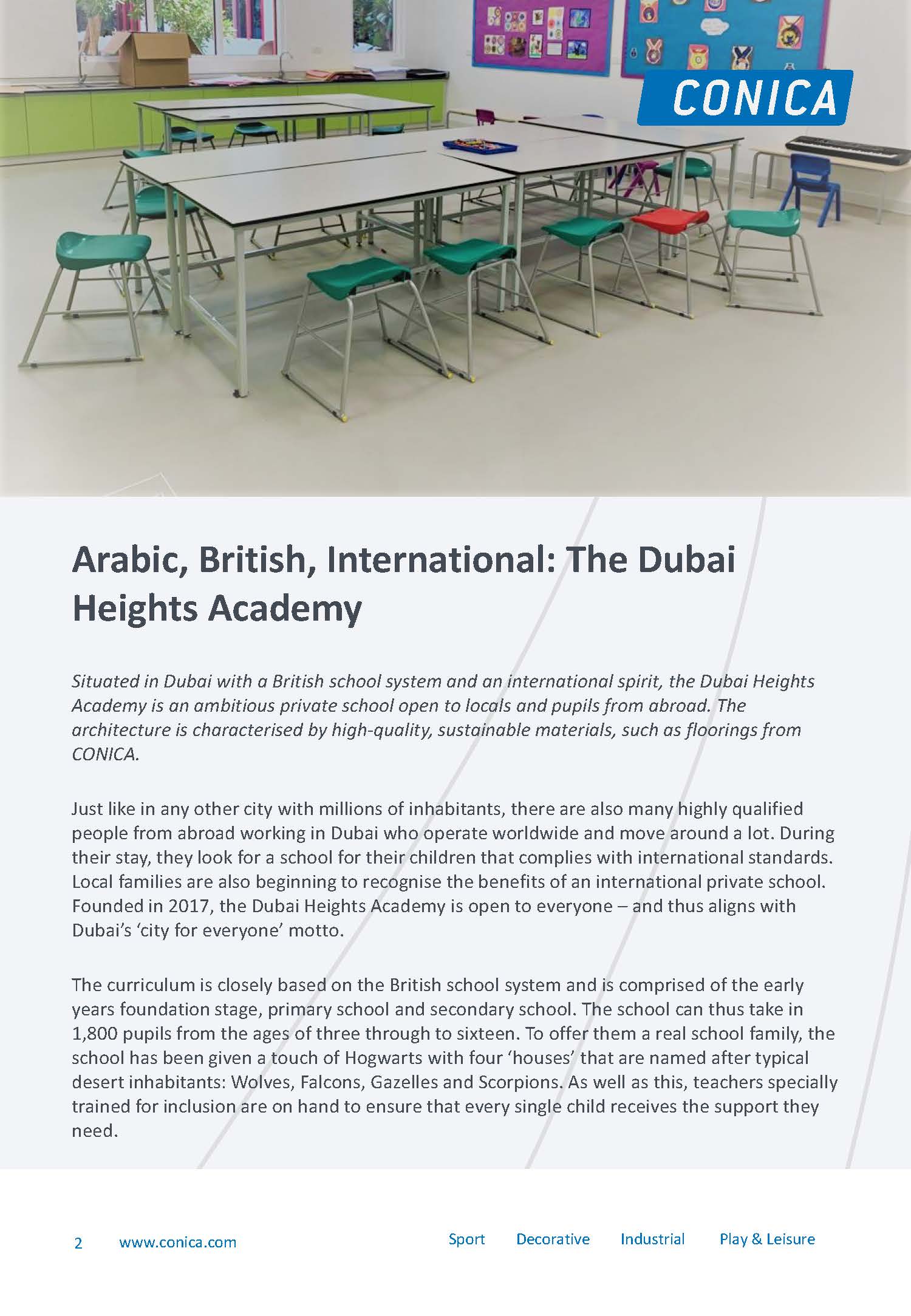

For the early years foundation stage, CONIFLOOR LPC or LPC+ were used (Image 1). CONIFLOOR LPC is a point-elastic and low-emission polyurethane self-levelling coating that is warm underfoot, anti-slip and absorbs footfalls and walking sounds. On the one hand, it absorbs the noise in the corridors when an entire group runs out for break time. On the other hand, it provides comfort when children are walking around in socks or barefoot. CONIFLOOR LPC+ was installed in the actual classrooms. This variant is equipped with an additional elastic and noise-absorbing underlay mat. It makes the flooring a little more flexible and thus cushions falls, which are naturally frequent occurrences in this age group.

CONIFLOOR IPS was the product of choice for the interior of the primary school. There is often a lot going on here as well. Perhaps the chairs and tables are rearranged and pulled roughly across the floor (Image 2). Or a water glass falls over while painting – no problem for this flooring, since it is impermeable (Image 3). In addition, it is equipped with a tough surface layer that can also withstand heavier loads.

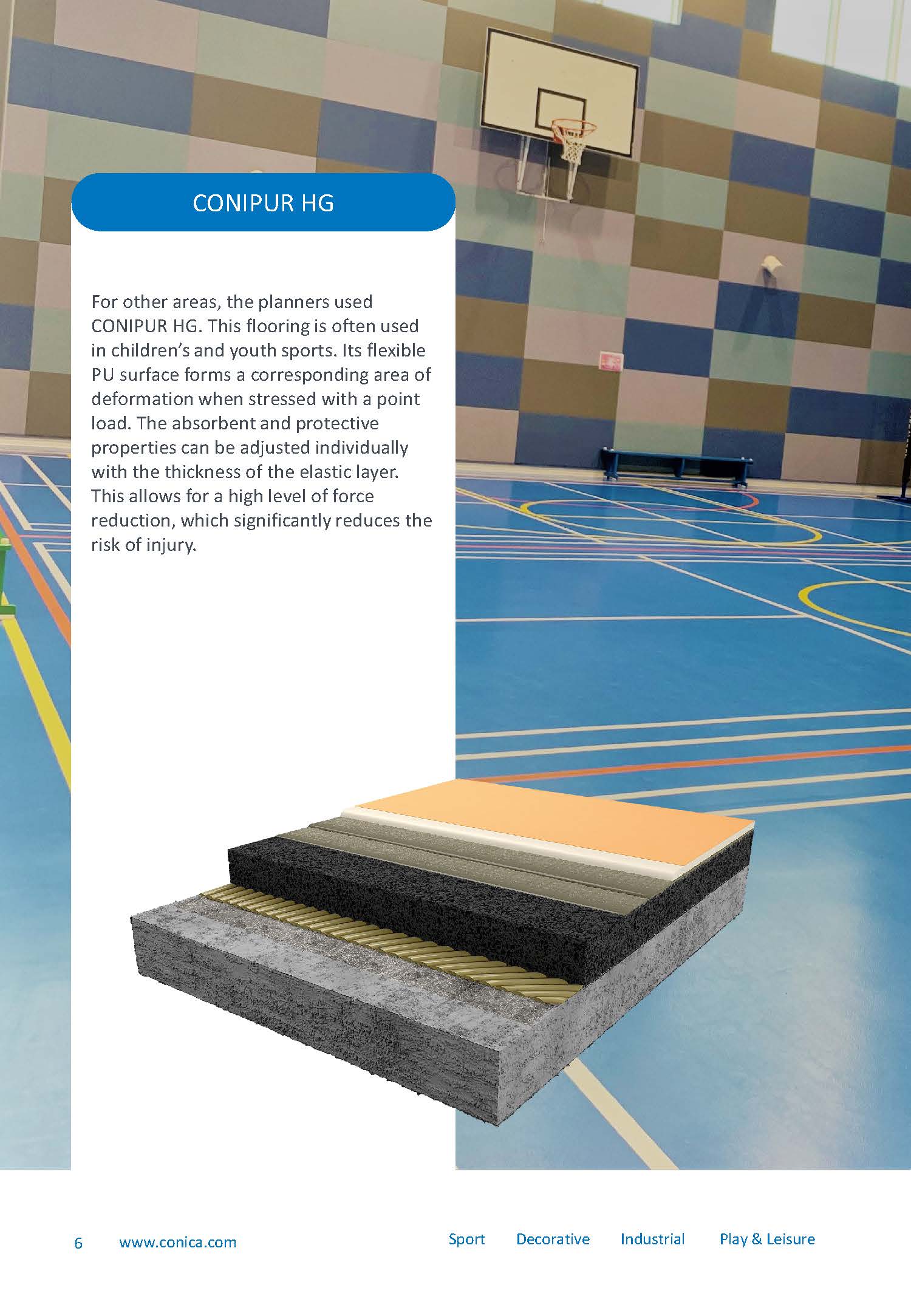

For other areas, the planners used CONIPUR HG. This flooring is often used in children’s and youth sports. Its flexible PU surface forms a corresponding area of deformation when stressed with a point load. The absorbent and protective properties can be adjusted individually with the thickness of the elastic layer. This allows for a high level of force reduction, which significantly reduces the risk of injury.

Fast installation in desert conditions

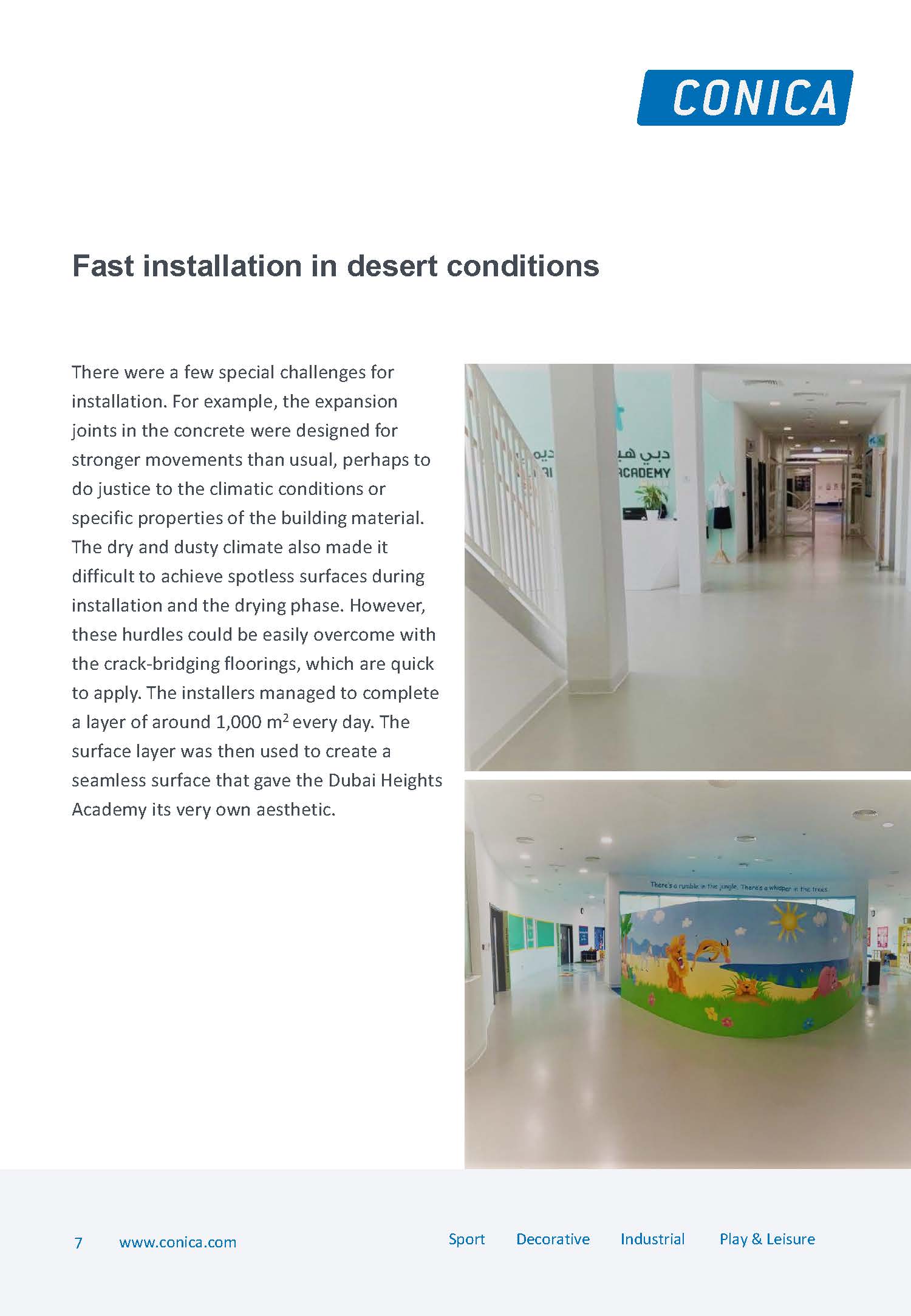

There were a few special challenges for installation. For example, the expansion joints in the concrete were designed for stronger movements than usual, perhaps to do justice to the climatic conditions or specific properties of the building material. The dry and dusty climate also made it difficult to achieve spotless surfaces during installation and the drying phase. However, these hurdles could be easily overcome with the crack-bridging floorings, which are quick to apply. The installers managed to complete a layer of around 1,000 m2 every day. The surface layer was then used to create a seamless surface that gave the Dubai Heights Academy its very own aesthetic.

Check out the Case Study about a special project. Download PDF